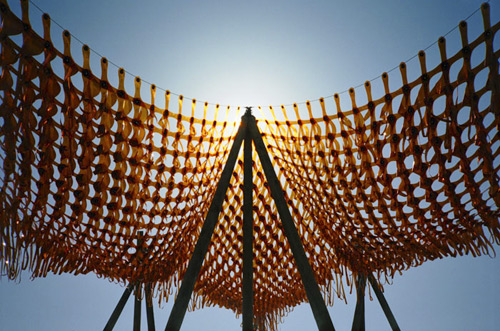

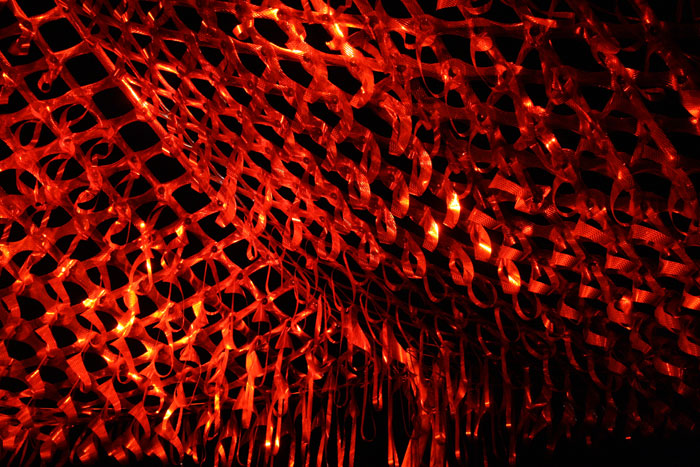

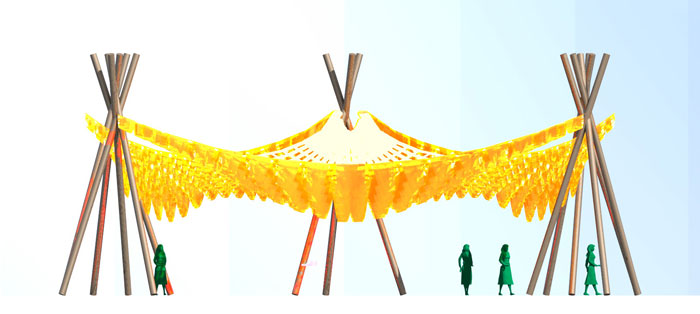

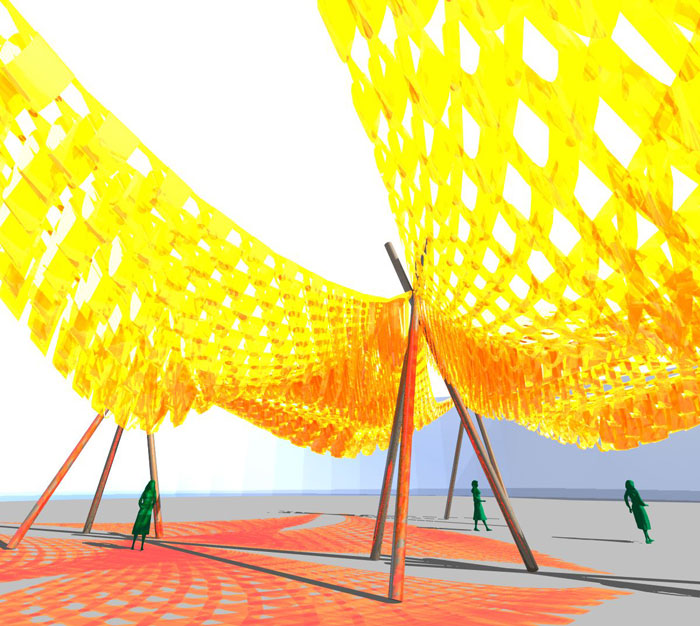

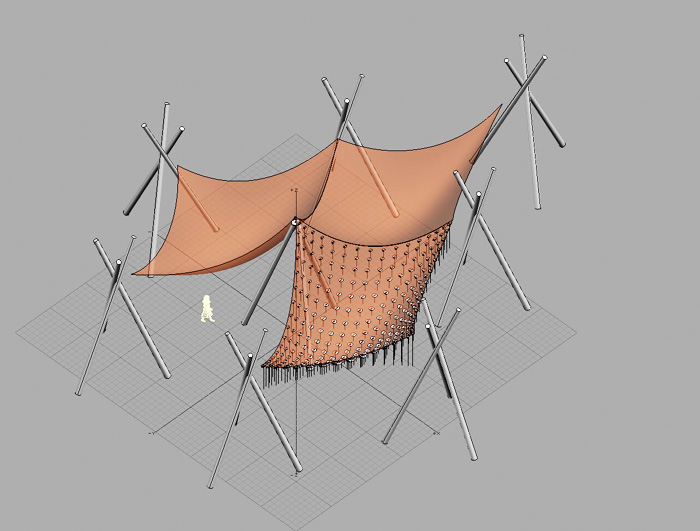

Unlike conventional fabric structures designed to resist the force of wind, Copper Droopscape actively engaged the breeze. The complex, 90-foot canopy translated wind energy into sensuous motions that festival goers compared to the sea, or a kelp forest undulating beneath the waves?? both delicious metaphors for a cool sanctuary, given the installation’s unforgiving desert site. The motion of the translucent canopy resulted in a hypnotic effect as light passed through and reflected off the Mylar network. In a light breeze, the canopy made a gentle rustling sound; during gusts, a pronounced clapping sound.

The canopy was supported by rapidly deployable tripods made of untreated California pine. After the festival, the tripods were repurposed by a local builder.

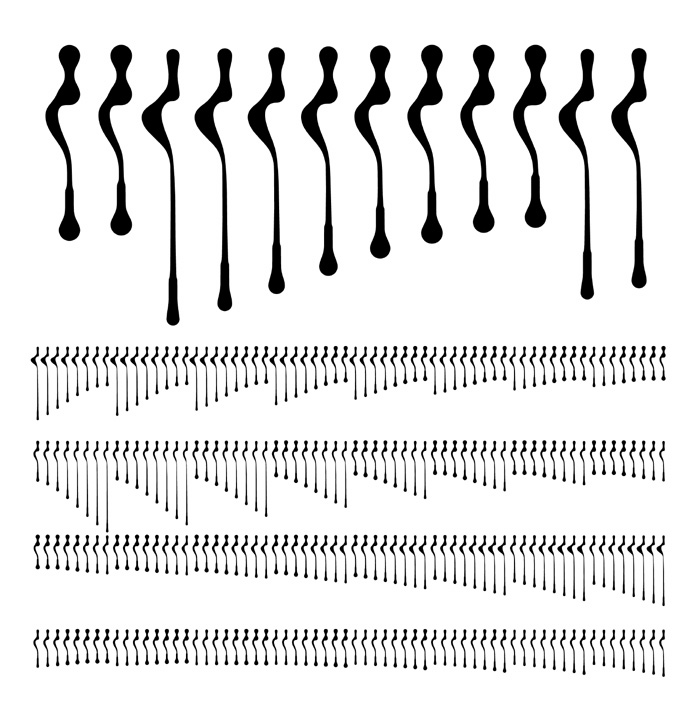

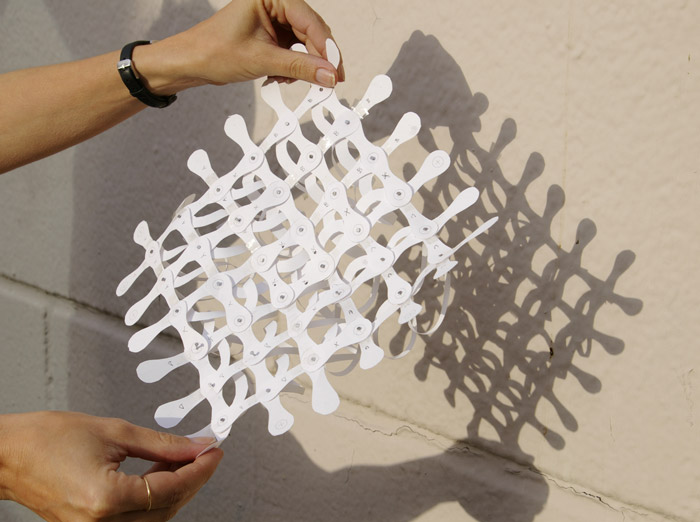

Copper Droopscape was a study in non-standard modularity. While it employed a uniform cell dimension, each of its 864 parts was unique. The standard cell made field assembly manageable, while each part’s non-uniform aspects?? the form and proportions of the hanging tendril?? yielded a rich visual and aural experience.

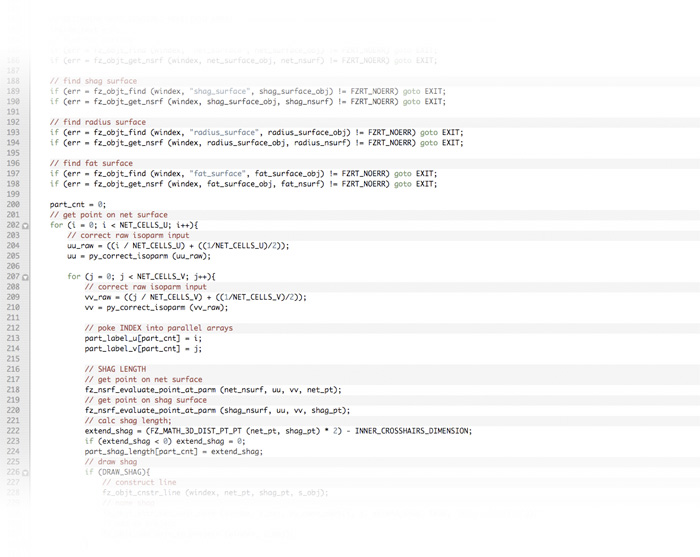

Ball-Nogues collaborated with Pylon Technical to create custom software to explore the form of Copper Droopscape, control the degree of openness in the canopy, and expedite fabrication. The software made formal exploration and revision fluid and effortless. Rather than drawing each of the unique mylar parts, Ball-Nogues sketched the qualities of the canopy in general terms, and the software automatically generated the hundreds of components making up the unified canopy system, labeled them, and prepared files to drive a computer-controlled cutting machine. The design and logistics were “front loaded” to reduce on-site management and fabrication complexity, which allowed Copper Droopscape to be assembled by a team of 12 people in just ten days.

Project Designers: Benjamin Ball, Gaston Nogues, Ben Dean, Andrew Lyon

Project Manager: Andrew Lyon

Project Team: Benjamin Ball, Chris Ball, Jodie Bass, Mark Bowman, Ryan Davis, Ben Dean, Martina Dolejs, Melissa Sophia Drocles, Christine Eyer, Richie Garcia, Eddie Gonzales, Oliver Hess, Josh Levine, Andrew Lyon, Reid Maxwell, Pie San Ng, Gaston Nogues, Charon Nogues, Nick Paradowski, Michelle Paul, Sarah Peyton, Geoff Sedillo, Andy Summers, Elizabeth Tremante, William Trossell, Erica Urech, Johanna Zuckerman

Software Development: Ben Dean of Pylon Technical

Photo credit: Alex Aristi, Chris Ball

'Pavilion&Installation' 카테고리의 다른 글

| [ Carmody Groarke ] Regent’s Place Pavilion (0) | 2010.01.31 |

|---|---|

| [ Ball-Nogues ] Maximilian's Schell, Materials & Applications, 2005 (2) | 2010.01.20 |

| [ IwamotoScott Architecture ] Voussoir Cloud (0) | 2010.01.17 |

| [ RUTA TURISMO RURAL SECANO INTERIOR ] LANDMARK (Escuela de Arquitectura, Universidad de Talca) (0) | 2010.01.16 |

| [ Ball-Nogues ] MOCA (0) | 2010.01.15 |