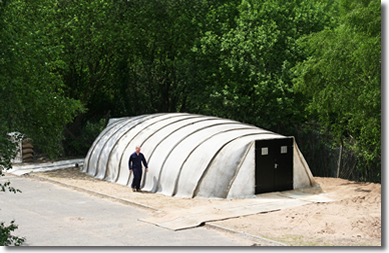

The key to CCS is the use of inflation to create a surface that is optimised for compressive loading. This allows thin walled concrete structures to be formed which are both robust and lightweight. CCS consist of a cement impregnated fabric (Concrete Cloth) bonded to the outer surface of a plastic inner which forms a Nissen-Hut shaped structure once inflated.

The Need

“While starvation occurs over a period of weeks, death from exposure can occur in a single night”

UN Co-ordinator for Afghanistan

There are currently over 35 million refugees worldwide. The aid agencies and troops that help save lives in emergency situations require accommodation, field offices and medical clinics. Current solutions are either soft-skinned and offer inadequate protection, or are expensive and difficult to transport. For example, in Afghanistan the useable life of some tents has been less than 3 weeks due to wind damage.

Concrete Canvas Shelters (CCS) have major advantages over conventional tented shelter:

1) Operational: CCS enables a hardened structure from day one of a crisis. It provides much better environmental protection, increased security and vastly improved medical capability.

2) Financial: CCS has a design life of over 10 years, whereas tents survive for only a few years and must then be replaced. CCS is a one stop solution, saving effort and cost over the lifetime of medium to long term operations.

2. KEYFACTS

Rapid: A 16m2 CCS can be deployed by 2 people in less than 40 minutes and is ready to use in 12 hours.

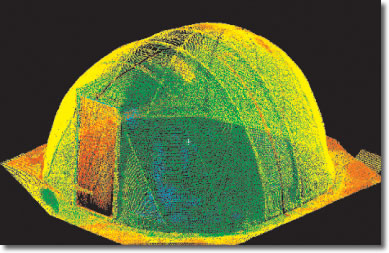

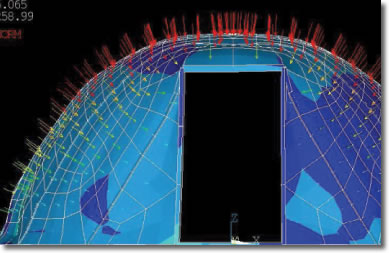

Force Protection: The compressive structure of CCS has been modelled for covering with sand or earth (berming) to provide protection against small arms fire and shell fragments.

Insulating: The concrete shell of a CCS has good thermal properties and when buried it provides excellent insulation, creating an encampment with a much reduced logistical footprint and low thermal signature.

Durable: CCS are far more durable than tenting with a minimum design life of 10 years.

Sterile/NBC: The sealed plastic inner of a CCS, means it can be delivered sterile; vastly increasing frontline medical capability from day one of a crisis. It is also possible to develop a shelter fitted with a forced air unit to provide full spectrum NBC, blast and shrapnel protection.

Secure: The hard shell and lockable doors of a CCS provide a level of security not possible with soft skinned structures, protecting stores, equipment and personnel.

Safe: The Concrete Cloth is a ceramic and will not burn.

Semi-permenant: CCS provides all the benefits of a permanent structure without the associated cost and time delays.

There are Four Stages of Deployment

Stage 1: Delivery

CCS are delivered folded in a sealed

plastic sack. The dry weight of a 16m2 variant is 500kg, light enough

for several to be transported on a pick-up truck or light aircraft.

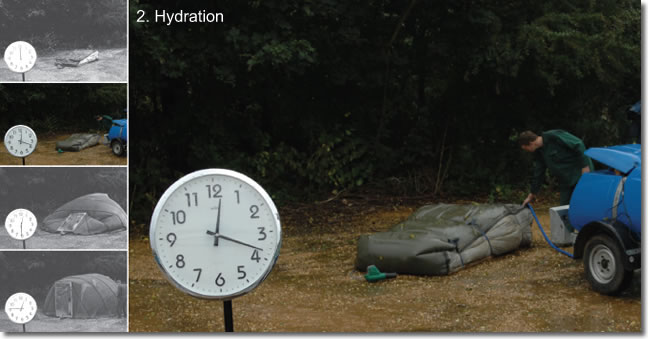

Stage 2: Hydration

The sack is positioned and filled

with water. The volume of the sack controls the water to cement ratio

eliminating water measurement. The bag is then left for 15 minutes

while the cement hydrates, this is aided by the fibre matrix which

wicks water into the cement. Once hydrated, the sack is cut along its

seams and forms part of the ground sheet. Deployment is done at dusk to

avoid over drying the cement.

The structure is unfolded to form the shelter’s footprint. A battery driven fan is activated which inflates the plastic inner to lift the structure until it is self supporting.

The Concrete Cloth cures in the shape of the inflated inner and 12 hours later the structure is ready to use. Service and access holes are left without Concrete Cloth bonded to the plastic skin. This allows A/C and heating units to be easily fitted once the cement has dried.

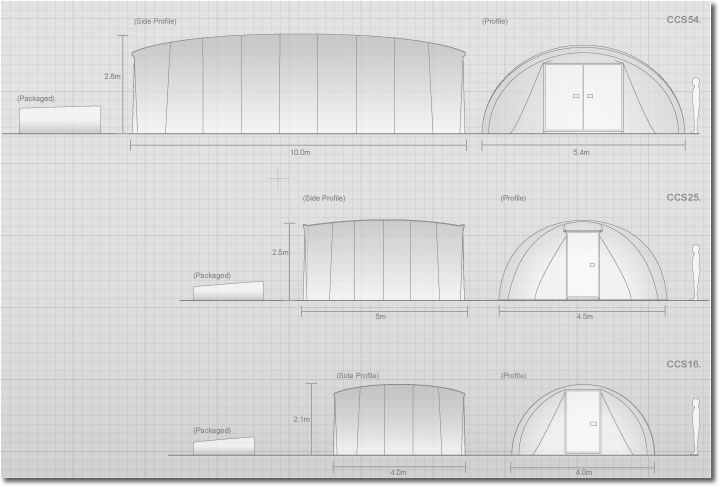

5. CONFIGURATIONS

Berming

The CCS structure have been modelled to withstand a very high distributed compressive load enabling earth berming by piling sandbags, earth or snow on top. This gives the shelter excellent thermal properties and can provide protection against shrapnel, blasts and small arms. Current systems are specified to withstand 0.75m wet sand on the sides, sufficient to stop 7.62mm rounds and 0.5m on the roof, to protect against shell fragments.

Linking

CCS structures are designed as part of a modular system; units can be easily linked together enabling the space to be tailored to the application. CCS is designed as a generic structure with initial uses as accommodation, field offices, and for secure storage. Future product developments include specialist medical variants and much larger shelters which could be used for applications such as storage of vehicles and helicopters.

Internals

CCS structures have been designed to maximize the internal usable

space. A standard CCS54 can accommodate up to 15 people according to

Sphere standards, Humanitarian and Disaster Response charter. For

longer term operations, CCS54 will accommodate 8 standard cots with

free standing mosquito nets, see diagram right.

6. PURCHASE

If you would like to purchase any of our Concrete Canvas Shelter units, please contact Concrete Canvas Ltd. directly, specifying how many units

'REF. > Debris' 카테고리의 다른 글

| Decorated trains in Japan (0) | 2008.12.04 |

|---|---|

| [ Eamon o'kane ] The architect's house (0) | 2008.12.03 |

| Podcast talk: Alan Aldridge at the Design Museum (0) | 2008.11.23 |

| Tezuka manga mutations (0) | 2008.11.22 |

| Dualiy Co, architecture in hi-def (0) | 2008.11.20 |