"전통은 과거의 유산이 아니라 현재를 통해 미래로 전달되는 살아있는 지혜이다." - 왕슈(Wang Shu)

|

|

|

굴루 워터프론트 목재다리 LUO studio -Timber Bridge in Gulou Waterfront

의례적 전환공간으로서의 설계 철학

굴루 워터프론트 리조트의 목재다리는 단순한 이동 수단을 넘어 공간적 경험을 제공하는 건축물로 계획되었다. LUO 스튜디오는 도시적 건축물과 차별화하고 전통 농촌 문화를 되살리기 위해 자연스러운 목재로 아치형 다리를 구현했다.

이 다리는 번화한 전통 상업가로 지역과 아동 놀이구역 사이의 경계에 위치하며, 두 공간의 성격 차이를 건축적으로 중재한다. 리조트 내 다른 개방형 경관다리와 달리 상대적으로 폐쇄적인 지붕이 있는 복도를 조성하여, 실용적인 상업가로에서 환상적인 아동 놀이구역으로의 전환을 강조했다. 방문객들은 이 복도를 지나며 공간 변화에 대한 의례감을 경험하게 된다.

구조적 측면에서는 다양한 크기의 선박 통행을 고려한 설계가 적용되었다. 평상시 수위보다 1.35m 높은 하중지지 플랫폼과 2.8m 높이의 아치형 구조가 결합되어 4m 이상의 통과 높이를 확보했다. 지질조사 결과를 바탕으로 설정된 25.2m 경간은 3개의 대형 곡선보로 지지되며, 각 보는 2.8m 간격으로 평행 배치되었다.

전통 건축 지혜의 현대적 계승

이러한 설계 접근은 춘추전국시대까지 거슬러 올라가는 덮개다리 건축 전통에 뿌리를 둔다. 고대 덮개다리의 초기 목적은 다리 구조를 강화하고 비와 습기로부터 목재를 보호하여 부식을 방지하는 것이었다. LUO 스튜디오의 이 프로젝트는 이러한 전통 건축 지혜를 현대적으로 계승하면서 새로운 기능적 가치를 더했다.

펄강삼각주 서부 지역의 풍부한 강우량을 고려하여 복도는 폐쇄적 형태로 계획되었다. 복도 외부를 감싸는 여러 층의 금속판은 효과적인 우수 차단 기능을 제공하는 동시에 공간의 통합감을 조성한다. 지붕이 있는 복도는 전체 구조의 안정성을 높이면서 아래쪽 아치형 목재 구조를 햇빛과 비로부터 보호하는 이중 기능을 수행한다.

제작과 운반의 효율성을 위해 각 주보는 세 부분으로 분할되어 현장에서 강화볼트로 조립되는 방식을 채택했다. 이는 전통적 목조 건축의 조립 원리를 현대적 제작 프로세스에 적용한 사례로 평가된다.

구조 혁신과 세부 구현

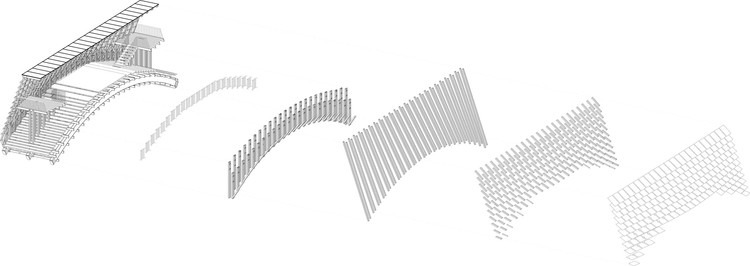

구조 시스템에서 주목할 점은 주구조와 보조구조의 위계적 분화이다. 600mm*300mm 단면의 3개 대형 곡선보가 다리 본체의 주요 하중을 담당하는 반면, 기타 목재 부재들은 100mm*100mm 또는 100mm*50mm의 소단면을 채택했다. 이러한 소형 목재 부재들은 주요 아치보에 맞물려 고정되어 상하 층의 보조보 역할을 수행하며, 양 끝은 상향 부재와 결합되어 안정적인 삼각력 구조를 형성한다.

공간적으로는 다리 지붕의 직사각형 평면과 측면 입면의 직선적 윤곽이 하단부 자연 곡선과 대비를 이루어 양쪽이 높고 중앙이 낮은 공간감을 조성한다. 구조 안정성 확보를 위해 중간 구간에 설치된 수평 연결봉과 양측의 조망 플랫폼은 기능적 필요와 시각적 다양성을 동시에 충족시킨다.

모듈 설계에서는 1,000mm로 설정된 보조구조 간격이 계단과 금속 외피의 스케일과 일치하도록 계획되었다. 인접한 보조보 사이에는 아치의 기울기에 따라 급경사 구간에 3개, 완만한 구간에 2개의 계단을 배치했다. 900mm로 제한된 외부 금속판의 길이는 제작과 설치의 효율성을 고려한 것으로, 동시에 한 사람이 서서 쉴 수 있는 적정 공간을 제공한다.

이러한 소단면 보조구조시스템은 복도 공간의 구조적 풍성함을 더하는 동시에 관광선 승객들에게 정교한 목조 장인정신의 디테일을 선보이며 독특한 시각적 체험을 제공한다.

Write by Claude & Jean Browwn

This project is a timber bridge, which is one of the many in Gulou Waterfront Resort. To differentiate it from urban constructions and revitalize traditional rural culture, LUO studio adopted natural wooden materials to construct an arched bridge. The resort provides access for small fishing vessels, as well as large tour ships. To enable boats of various sizes to pass under the bridge smoothly, the load bearing platform at the bottom of the arch which is 1.35m higher than the normal water level, combined with the 2.8m arched structure, forms a space more than 4m higher than the normal water level. This meets the clearance requirements for large tour boats to pass through. Based on geological surveys, the span of the bridge is set at 25.2m. Through structural calculation and construction analysis, LUO studio utilized 3 large curved beams as main structural components, which are arranged in a parallel manner with a 2.8 spacing between each other. With full consideration of manufacturing and transportation costs, each main beam was divided into three sections at appropriate positions, connected and assembled by steel-strengthened bolts on the site, to form the complete wooden beam.

Set covered corridor on the bridge. The ridge is located in the joint area between a dense traditional commercial street area and a children's recreation area. LUO studio created a relatively "closed" corridor space on the timber bridge, which is different from other open landscape bridges in the resort. The aims were to accentuate the transition from the "practical" commercial street area to the relatively "dreamy" children's recreation area, allowing visitors to feel a sense of ceremony in the moving process.

Constructing a covered corridor on bridges has been an old tradition that dates back to the Spring and Autumn Period and the Warring States Period. The initial intention was to strengthen the bridge structure, resist rain and moisture, keep the wood dry and prevent it from corrosion. This project also inherits the construction wisdom of ancient covered bridges. The covered corridor enhances the overall structural stability and protects the arched wooden structure beneath from exposure to sun and rain. The west area of the Pearl River Delta where the timer bridge is located has abundant rainfall, so the corridor was constructed in a relatively closed form. The exterior of the corridor space is covered by layers of metal plates, which effectively protect it from rain and also create a sense of cohesion for the space.

Covered corridor construction. Sub structural system formed by wooden components with small sections apart from the three large wooden arched beams that bear the main load of the bridge body having a section size of 600mm*300mm, other wooden components adopt small sections. They are either 100mm*100mm or 100mm*50mm. Small wooden components are interlocked and anchored to the three main arched beams, functioning as sub-beams on upper and lower levels. In addition, the two ends of these sub-beams are combined with upward components to form a stable triangle of forces.

The plane of the bridge's roof is a complete rectangle. The top, left, right edges of the bridge's side facades also consist of rectangular silhouettes, while only the lower edge is a natural curve. This generates height variations of the corridor space that is higher on the two sides and lower in the middle. To ensure the structural stability of the covered corridor space, the design team set horizontal connecting rods in the middle section and added two viewing platforms on either side, which also avoid the monotonous feeling when viewing the corridor space from the entrance and exit. The small-section sub-structural system not only enhances the sense of structure in the corridor space but also reveals the elaborate craftsmanship and details to visitors on tour boats and offers them a unique visual experience.

Construction modules & material specifications. The small scale wooden components are arranged with small spacing in between. The spacing between neighboring substructures is set at 1,000mm equally. This perfectly matches the scales of the steps and metal exteriors. Between neighboring sub-beams, three steps are set at the steep sections of the arch, while two steps are set at the gentle sections. The length of each external metal plate is controlled at about 900mm, which is appropriate for manufacturing, transporting, and installation. The 900mm length of timber frames also provides a suitable space for a single person to stand, lean, and rest.

from archdaily